300mm Yanagiba

300mm Yanagiba in D2 steel with a Wenge and Bronze handle and a saya in Red Gum Burl

280mm Kiritsuke

The blade is made from DIN 115W8 (1.2442) a specialised knife steel made by Lohmann-Stahl in Witten, Germany and is only made to specification for Achim Wirtz (which is who I buy steel from). The inclusion of 2.0% Tungsten makes the steel very tough and hard wearing; by general definition this is a High Carbon Steel so in normal use it will take on a patina which has no effect on its performance. Heat treated to 62 Rockwell.

The handle is Maple Burl with a traditional buffalo horn ferrule and a bronze spacer and cap. The bronze is part of my limited supply of Admiralty Bronze which originated some 40 year ago from the now defunct Woolwich Arsenal.

The Saya is made from Bog Oak and is intended to keep the knife and the user safe so it is held in place with a bronze and nickel silver pin.

5” Fixed Blade Hunter

This Drop Point Hunter has been formed from a piece of Damasteel’s Damascus patterned stainless steel; this is a highly specialised powder steel with two alloys, RWL34TM and PMC27TM, which can be seen in the etched surface.

Powder steel is manufactured in a complicated process by heating the ore to its melting point, the the molten steel is then atomized by inert gas jets into fine metal droplets; the droplets cool down during their descent in the atomizing tower.

After the atomization, the steel is formed in process called Hot Isostatic Pressing where the metal powder is placed in a pressure vessel that is filled with inert Argon gas, the temperature is raised to the melting point of approximately 1300 degrees C and the gas pressure is increased to 15,000 lbs per square inch. In this environment the gas pressure acts uniformly in all directions, and forms the steel powder into a single molten mass. The molten steel is then poured into ingot moulds and then further processed into large billets and into manageable strips.

The actual billet for the knife is formed by layering the two steels into seven alternating bands and then forging them into a single billet at high temperature; the billet is then folded, twisted, flattened and coined to produce the finished Gysinge pattern. All this is done by Damasteel; the complexity is represented in the cost of the material.

On receipt of the steel, I then made the blade by a process of shaping, grinding, machining, heat treatment, finish grinding and hand polishing. The finished blade was then etched in concentrated Ferric Chloride to produce the visible surface pattern.

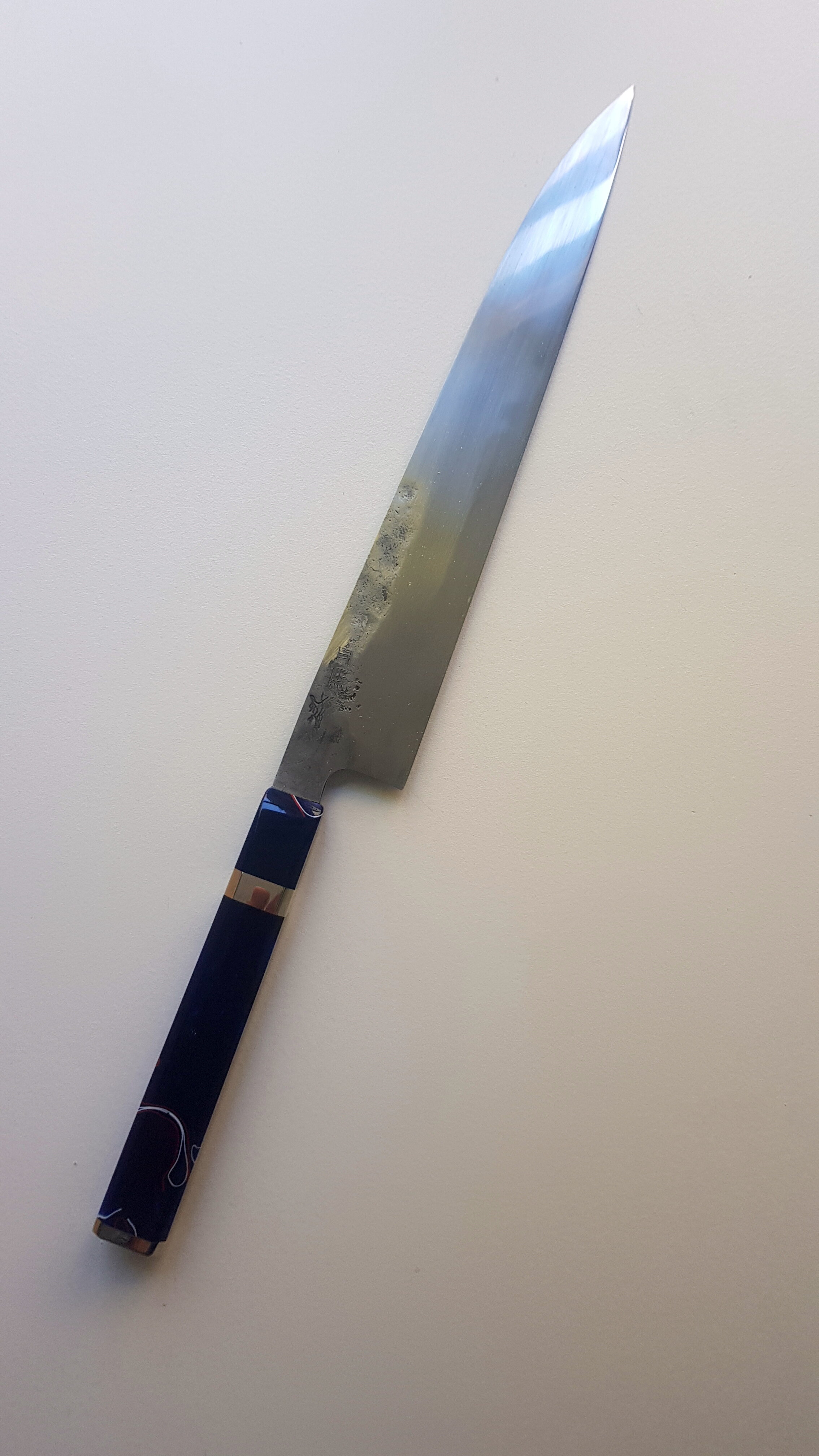

240mm Gyutohiki

This Gyutohiki slicer was made from 14C28N cutlery steel; this is a super fined-grained steel made by Sandvik in Sandviken, Sweden. It is their best quality steel and has the optimized chemistry required for a top-grade knife steel to provide a unique combination of excellent edge performance, high hardness and good corrosion resistance. Heat treated to 61.5 Rockwell C.

The handle and saya are made of Wenge a timber from central Africa, the handle a has a nosing, spacer and cap of bronze which was liberated many years ago from the now defunct Woolwich Arsenal.

220mm Kiritsuke

The blade is 1.2442 is very similar to Hitachi Aogami 1 steel, with a fraction less Carbon and Chromium, but more Tungsten which makes it very hard wearing.

The handle is Snakewood (Brosimum Guianense) and originates in the north eastern regions of South America, the handle has a silver spacer and a traditional buffalo horn nosing.

The Saya is made from Black Ebony and is intended to keep the knife and the user safe so it is held in place with a nickel silver pin.

Gyuto

The blade is hand-made from 52100 steel also known as AISI L3 and is mostly recognised in its use for ball bearing manufacture.

The composition is nominally Carbon 1.0%, Chrome 1.3 – 1.7%, Vanadium 0.1 – 0.3%, Manganese 0.25 – 0.8%, Silicon 0.25 – 0.8%. it was heat treated to 62 Rockwell.

The handle is French Hornbeam and has been stabilised so that it is water resistant, the spacer is a substitute ivory.

175mm Gyuto

This Gyuto was forged from a piece of D.I.N. standard 1.2442 carbon tool steel that is produced is a specialised foundry in Germany. It is one of the highest quality knife steels available anywhere. The Japanese kanji on the blade says Hakuba which means White Horse like the white horse of Kent which I use as my maker’s.

After forging and profiling the blade, I stress relieved it at 730 degrees C for 30 minutes and allowed it to cool. It was then heated in stages to 830 degrees C., quenched in oil heated to 70 degrees C and then tempered twice at 180 degrees for 1 hour. This has resulted in a hardness of 64 degrees on the Rockwell C scale. The handle is Snakewood (Brosimum Guianense).

165mm Deba

The Deba is primarily a preparation knife for fish and poultry. The blade is 14C28N cutlery steel; this is a super fined-grained steel made by Sandvik in Sandviken, Sweden. It is their best quality steel and has the optimised chemistry required for a top-grade knife steel to provide a unique combination of excellent edge performance, high hardness and good corrosion resistance.

The handle is made from 200 year old English Box Wood and the ferrule is African Ebony.

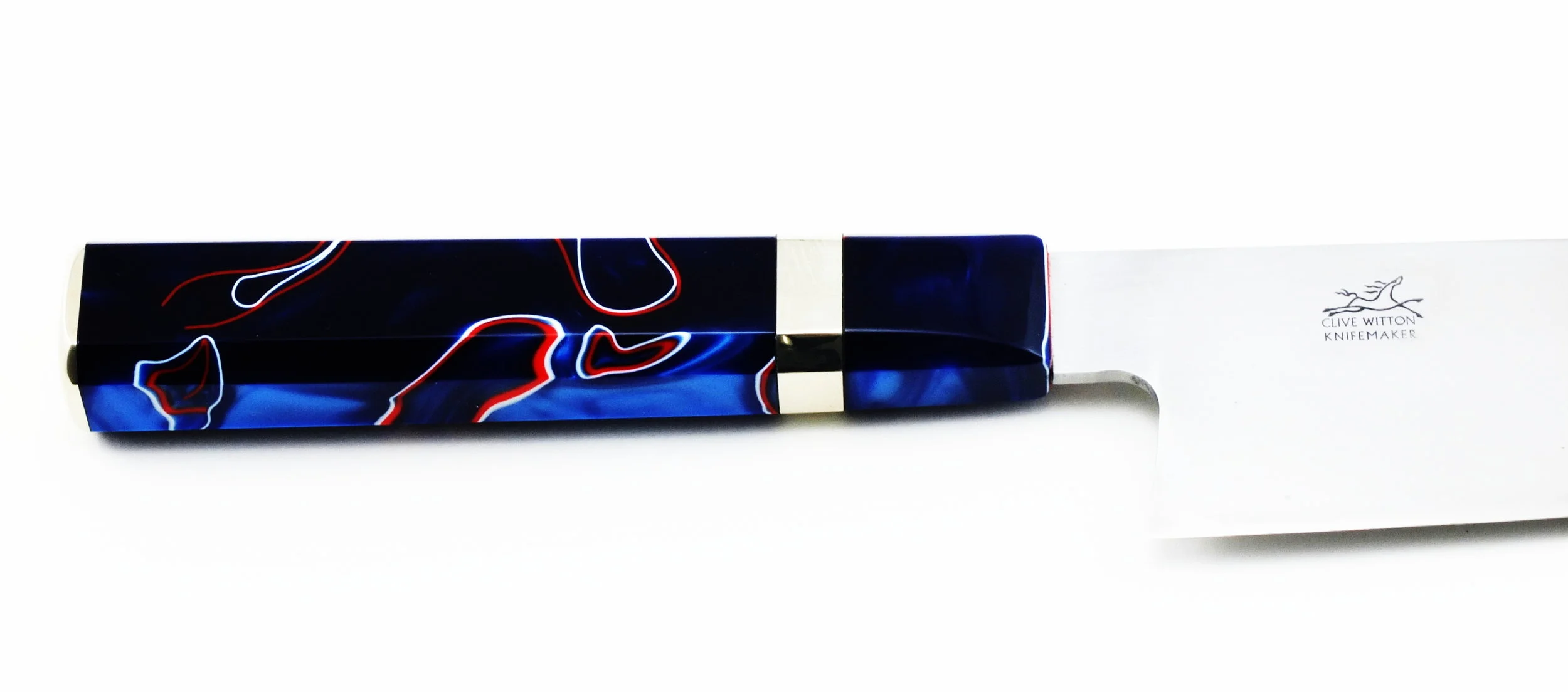

270mm Gyutohiki

The Gyutohiki is for general food preparation, slicing and carving and has been hand forged in the traditional Japanese style. The blade is made from Japanese Aogami Blue Paper 1 steel (so called because it is sold in blue paper!). This is a very pure, high carbon steel with added Tungsten and Molybdenum which provide addition toughness. It is recognised as probably the world’s best steel for kitchen knives.

The handle is made from Kirinite with Nickel Silver fittings. This is an artificial plastic which actually has its origins on the button making industry around Milan but is made for and sold by a UK company. This piece of Kirinite is part of a unique sheet that they made solely for me at 40mm thick so it is unlikely to be replicated. The red, white and blue pattern is called Patriot.

200mm Gyuto

This 200mm Gyuto is hand forged from a piece of Damascus composed of types 1090 and 15N20 Carbon Steel. The steel was made by forging together the two steels then folding and then twisting them to produce a solid billet with approximately 220 layers which provides the patterning in the steel.

The final process is to etch the finished blade in ferric chloride; compared to the 1090, the 15N20 has a small percentage of Nickel which resits the etch and shows up as the brighter layers.

The handle is Snakewood (Brosimum Guianense) and has a silver spacer and a traditional buffalo horn nosing.

Slim Hunter

I have made this Slim Hunter knife and its sheath entirely from the very best materials.

It has a hollow-ground, drop point blade 3 3/4″ long and 0.130″ thick with a distal taper to the point and through the tang. The handle is Mammoth Ivory, between 10,000 and 50,000 years old and comes from the Sakha Republic in Yakutia province, North East Russia. The guard and Corby bolts are made from nickel silver.

The blade is Sandvik’s 14C28N steel which is the latest development in their range of knife steels. The steel’s optimized chemistry provides for a top grade blade with a unique combination of excellent edge performance, high hardness and good corrosion resistance; it was heat treated to 61 Rockwell.

The hand made and hand stitched leather sheath is in vegetable tanned hide which has been dyed and treated with a preservative.

150mm Petty

The blade is hand-made from 52100 steel also known as AISI L3 and is mostly recognised in its use for ball bearing manufacture.

The composition is nominally Carbon 1.0%, Chrome 1.3 – 1.7%, Vanadium 0.1 – 0.3%, Manganese 0.25 – 0.8%, Silicon 0.25 – 0.8%

This is by general definition a High Carbon Steel so in normal use it will take on a patina which has no effect on its performance.

The handle is Black Ebony and it has a ferrule of Buffalo Horn.

10 Inch Cook's Knife

A large cook's knife in Sandvik 14c28n, heat treated to 62 Rockwell C. Kirinite Patriot handle with nickel silver fittings.

A custom set made to a client’s exact requirements. All in Sandvik 14C28N steel heat treated and cryo-quenched to attain 61 Rockwell C, with Neolithic Bog Oak handles secured with nickel silver corby bolts. The set was supplied with each knife was in a leather sheath, fitted into a canvas lined leather Knife Roll fitted within a canvas holdall.

150mm Deba

A 150mm long Japanese Deba knife for a right-handed user. The blade is Sandivk 14c28n and heat treated to 62 Rockwell. The handle is made with Box Wood and Bog Oak.

A set of Kitchen Knives

This set of knives were hand forged from a single piece of San Mai made by Takefu Special Steels of Japan, the core is Shirogami 2 (a high carbon knife steel), the cladding is ordinary Carbon Steel and is separated from the core by a thin layer of Nickel which shows as the silvery line.

The handles are Neolithic Oak from Suffolk. This species of massive oaks, with straight trunks almost 100ft high to the crown, is now extinct. When the European ice caps melted, the North Sea rose and isolated England, the trees lost their footings in the rising water and eventually fell where relatively few were preserved by the anaerobic action of the peaty soil which is why it is almost black. This specific oak has been radiocarbon dated at 5,000 years old and is thus older than the Pyramids at Giza and, older than Stonehenge.

165mm Cleaver

This Cleaver was hand-forged from SC125sc a high carbon steel made in a foundry in Witten, Germany that only produces specialised steels. 125sc is smelted from Armco pure iron #4 (the purest commercially available iron) arguably this is amongst the finest carbon knife steels in the world.

After hand forging and profiling the blade, I annealed it by heating to 820degrees C and then leaving it in the furnace to cool slowly so that the steel, having been heavily deformed by forging, was returned to its original un-stressed condition before heat treatment; this avoids stress cracking in the furnace. It was then heated to 850 degrees C., quenched in heated oil and then tempered (twice) at 175 degrees for 45 minutes; it measures 62 degrees on the Rockwell C scale.

The handle is made from Snakewood (Brosimum Guianense) which only grows in the coastal regions of N.E. South America. It is shaped in the traditional Japanese Wa style of octagonal profile and has a pure Silver spacer.

155mm Nakiri

This Nakiri was hand-made from 52100 steel also known as AISI L3 and is mostly recognised in its use for ball bearing manufacture.

The composition is nominally Carbon 1.0%, Chrome 1.3 – 1.7%, Vanadium 0.1 – 0.3%, Manganese 0.25 – 0.8%, Silicon 0.25 – 0.8% and was heat treated to 62 degrees on the Rockwell C scale.

The handle is stabilised Australian Coolabah burl it has been stabilised so that it is water resistant, the spacer is coper.

155mm Nakiri

The blade is hand-made from 52100 steel also known as AISI L3 and is mostly recognised in its use for ball bearing manufacture.

The composition is nominally Carbon 1.0%, Chrome 1.3 – 1.7%, Vanadium 0.1 – 0.3%, Manganese 0.25 – 0.8%, Silicon 0.25 – 0.8%. Heat treated to 62 degrees on the Rockwell C scale.

The handle is French Hornbeam and has been stabilised so that it is water resistant, the spacer is a substitute ivory.

Drop Point Hunter

This knife is a Drop-Point Hunter in the style of Bob Loveless. The hollow ground blade is 4 3/8″ long and the cutting edge is 4″ x .160″ thick with a distal taper in both directions from the guard. The blade is made from Hitachi Metals’ ATS-34 which was Bob Loveless’ preferred steel, it is stainless, corrosion resistant and very durable.

The handle is Forest Green micarta with red liners all secured with nickel silver Corby Bolts and a nickel silver finger guard – again Loveless’ preferred materials.

The hand-made and hand-stitched leather sheath is a vegetable tanned hide which has been dyed and treated with preservative; the application of clear or red shoe polish will keep it in good condition.

270mm Gyuto

The blade is hand-made from 52100 steel, AISI L3 and is mostly recognised in its use for ball bearing manufacture.

The composition is nominally Carbon 1.0%, Chrome 1.3 – 1.7%, Vanadium 0.1 – 0.3%, Manganese 0.25 – 0.8%, Silicon 0.25 – 0.8% . After shaping and profiling the blade I stress relieved it at 780 degrees C. It was then heated to 845 degrees C., and quenched it in hot oil and then tempered (twice) at 180 degrees for 60 minutes. This has resulted in a blade hardness of 62 degrees on the Rockwell C scale, so it will hold a sharp and effective edge.

The handle is French Hornbeam and has been stabilised so that it is water resistant, the spacer is a substitute ivory.

200mm Gyuto

This Gyuto is specifically intended for general food preparation. The blade is hand-made from DIN 115W8 (1.2442) a specialised knife steel made by Lohmann-Stahl in Witten, Germany.

1.2442 is by general definition a High Carbon Steel with additional alloying elements including approximately 2.0% Tungsten which makes it very tough and hard wearing. In normal use it will take on a patina which has no effect on its performance. Heat treated to 62 Rockwell. The handle is Snakewood (Brosimum Guianense) and has a silver spacer and a traditional buffalo horn ferrule.

175mm Boning Knife

This Boning Knife Is IN 14C28N cutlery steel; this is a super fined-grained steel made by Sandvik in Sandviken, Sweden.

It is their best quality steel and has the optimized chemistry required for a top-grade knife steel to provide a unique combination of excellent edge performance, high hardness and good corrosion resistance. The blade was hardened and tempered to achieve a hardness of 62 degrees on the Rockwell C.

The handle is made from Black Micarta and has red liners; micarta is waterproof and hygienic for food use. However, the knife should never go in the dish washer; a simple wipe will get it clean and, as its stainless, it will not rust.

225mm Gyuto

This 225mm Gyuto has been hand forged from a piece of San Mai made by Takefu Special Steels of Japan, the core is Shirogami 2 and the cladding is Carbon Steel.

After forging and profiling the blade, I stress relieved it at 780 degrees C for 30 minutes and allowed it to cool over 6 hours. It was then heated in stages to 800 degrees C., quenched in oil heated to 70 degrees C and then tempered at 120 degrees for 2 hours. This has resulted in the core steel being very fine-grained and having a retained hardness very close to 65 degrees on the Rockwell C scale. It is hard but will re-sharpen and hold a sharp and effective edge; the carbon cladding provides some flexibility in accordance with Japanese tradition.

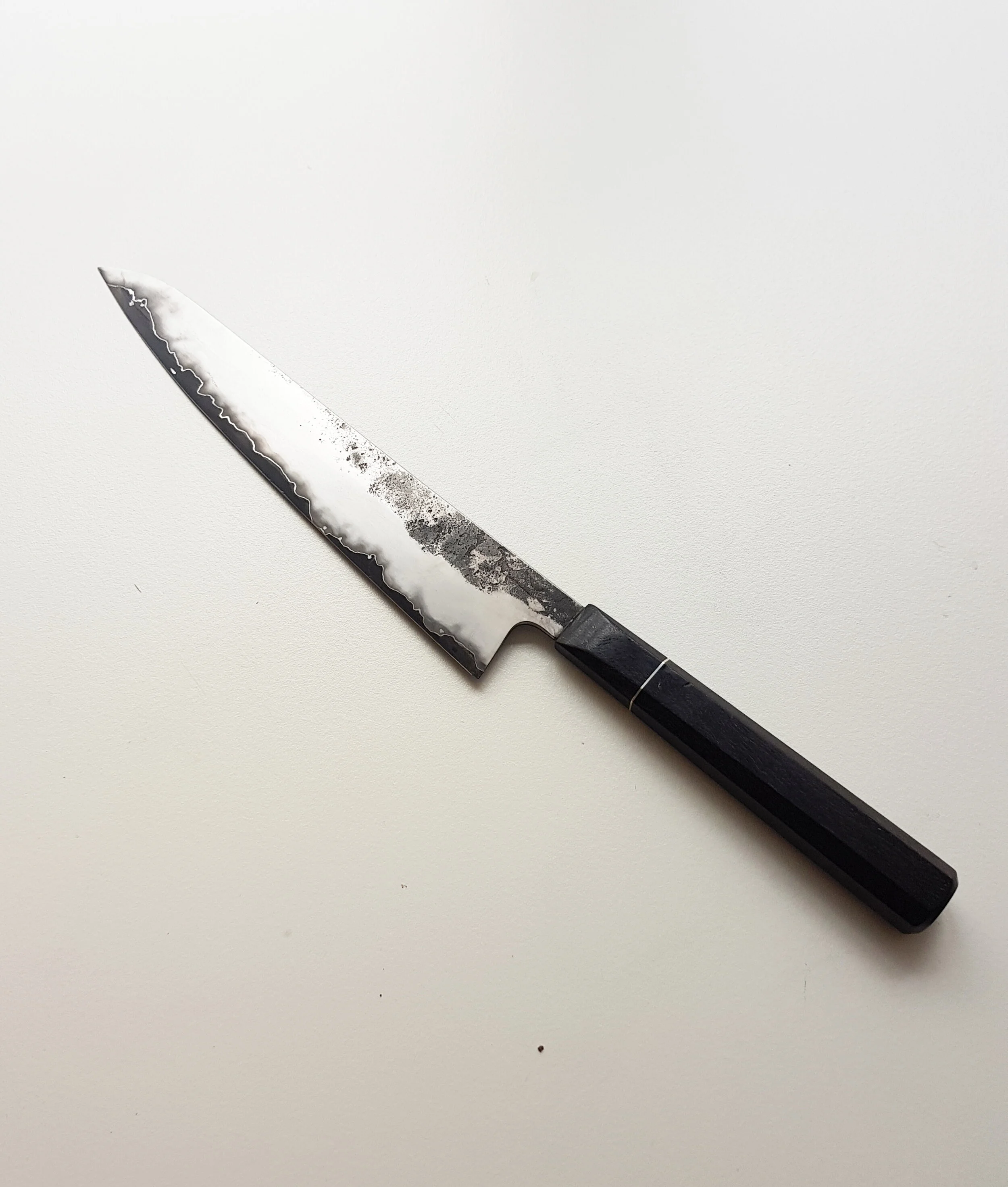

220mm Gyutohiki

This Gyutohiki has been entirely handmade from hand-forged from SC125sc a high carbon steel made from Armco pure iron #4 (the purest commercially available iron), in a foundry in Witten, Germany that only produce specialised steels. Currently this is arguably one of the finest carbon knife steels in the world.

After forging and profiling the blade, I annealed by heating it to 820degrees C and then leaving it in the furnace to cool slowly which, if the steel has been heavily deformed by forging (which of course it had been) then the pearlite and ferrite in the steel’s microstructure interact to form the alloy banding that is evident. It looks a little like the blade is Damascus steel but that is an entirely different manufacturing process.

Prior to hardening the blade, I coated it with clay to produce a differentially hardened blade with a Hamon line in the style of Japanese knives. It was then heated to 850 degrees C., quenched in oil and then tempered (twice) at 175 degrees for 45 minutes.

However, when I polished it after hardening it showed the banding and a hamon line (the pale silver-slightly whispy line) between the banding and the hard cutting edge which, from a nerdy perspective is metallurgically interesting but, does explain the appearance. The cutting edge has a hardness of 64 degrees on the Rockwell C scale.

The handle is made from Ebony in the traditional Japanese octagonal profile and has a pure Silver spacer.

Drop Point Hunter

The blade is formed from Sandvik 14C28N cutlery steel; this is a super fined-grained steel made by Sandvik in Sandviken, Sweden. The blade was hardened at 1050 degrees C, cooled to -20 degrees and then tempered twice at 175 degrees for 2 hours. This has resulted in a hardness of 62 degrees on the Rockwell C scale; it will hold a sharp and effective edge.

The handle is Olive Drab Micarta secured with nickel silver Corby Bolts. The hand stitched sheath is formed from 3mm thick hide and stained and polished to suit.

Made specifically for slicing, this blade is flat on the left hand side, for a right-handed user; the as-forged finish on the right hand side assists food release during use. The O1 tool steel blade is heat treated to 62 Rockwell C and will retain a very sharp edge during prolonged use. The case and the asymmetric handle are both Neolithic Oak.

Specifically designed for outdoors days including picnics, this small knife with a 80mm long blade will stay safe in the hamper but will also deal with all your food preparation need. The blade is Sandvik 14C28N cutlery steel which is a super fined-grained steel made by Sandvik in Sandviken, Sweden. The blade is hardened at 1050 degrees C, cooled to -20 degrees and then tempered twice at 175 degrees for 2 hours. This has resulted in a hardness of 62 Rockwell C.

The handle is Amboina burl, secured with nickel silver Corby Bolts. The hand stitched sheath is 3mm thick hide stained and polished to suit.

Boning Knife

This Boning Knife blade is 14C28N cutlery steel; this is a super fined-grained steel made by Sandvik in Sandviken, Sweden. Heat treated to 62 degrees on the Rockwell C scale; it will hold a sharp and effective edge. The steel contains 14% chromium, so it is highly corrosion and stain resistant. The handle is made from Black Micarta and has red liners; micarta is waterproof and hygienic for food use so is ideal for kitchen use.

200mm Gytuo

A 200mm Gyuto in DIN 115W8 (1.2442) Carbon steel, Handle in Snakewood, Silver and Buffalo Horn.

Pairing Knives

Three Paring Knives blades all in 125sc Carbon Steel the top knife with a Coolabah Burl and Silver handle the lower two knives in Maple Burl with Copper spacers

210mm Sujihiki

This slender Sujihiki is in O1 tool steel and has been heat treated to 64 Rockwell. O1 is a great steel, vastly underrated, it is as tough, durable and reliable as they come.

The Black Palm and Buffalo horn for the handle make a very satisfying and subtle combination.

265mm Gyuto

A Gyuto 265mm long forged from a truck leaf spring, its was heat treated to 62 Rockwell. The point of balance is just in front of the handle which is made from Olive wood and Buffalo horn.

320mm Sujihiki

320mm Sujihiki in 125sc and 304L San Mai with a Snakewood, Silver and Buffalo Horn handle and a Lemonwood saya.

95mm Drop Point

It has a hollow-ground, drop point blade 3 3/4″ long and 0.130″ thick with a distal taper to the point and through the tang. The handle is beautiful Mammoth Ivory, which is approximately 100,000 to 150,000 years old, and the guard and corby bolts are made from nickel silver.